What Does Inventory Management Do?

Wiki Article

How Inventory Management can Save You Time, Stress, and Money.

Table of ContentsThe Best Strategy To Use For Inventory ManagementThe 10-Second Trick For Inventory ManagementThe 5-Second Trick For Inventory ManagementNot known Incorrect Statements About Inventory Management

There are two major methods of keeping an eye on stock: periodic as well as continuous. The major difference in between these is how typically data is upgraded. Regardless of how often you track supply, you may intend to utilize one of the complying with inventory administration methods: ABC Analysis, ABC (Always Better Control) Analysis is stock management that divides different things into three classifications based upon pricing and also is separated right into teams A, B, or C.EOQ Design, Economic Order Quantity is a technique utilized for planning and getting an order quantity. It involves making a decision concerning the amount of inventory that ought to be positioned in supply at any type of offered time.

FSN Approach, This approach of stock control describes the procedure of monitoring all the things of supply that are not used frequently or are not needed at all times. They are after that classified right into 3 different categories: fast-moving inventory, slow-moving supply, as well as non-moving stock. JIT Technique, In the nick of time inventory control is a procedure made use of by manufacturers to regulate their supply levels.

:max_bytes(150000):strip_icc()/inventory-management-8595e839c2884128997ca77f00a8da2b.jpg)

Inventory Management Fundamentals Explained

VED Analysis, VED is a strategy utilized by companies to regulate their inventory. The high degree of inventory that is required for manufacturing normally validates the low inventory for those components.Wrike's product launch automation helps accelerate item launches with a structured strategy.

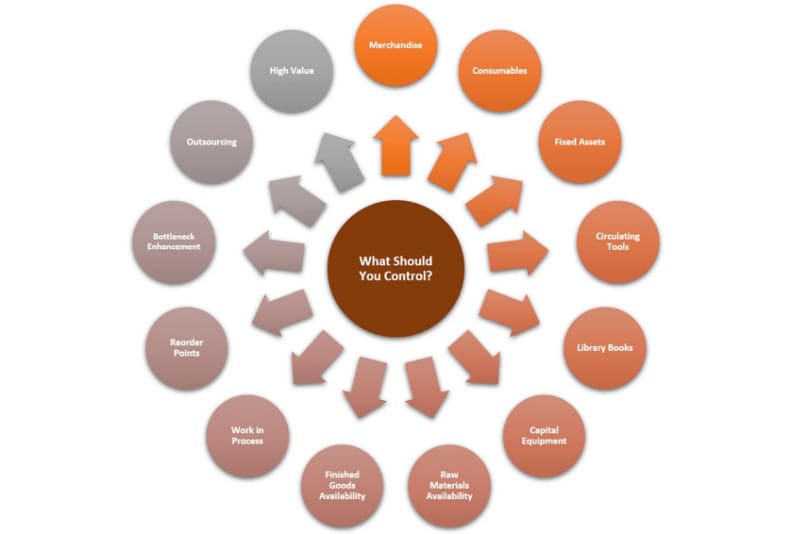

Inventory monitoring tries to efficiently simplify inventories to stay clear of both excess as well as shortages. 4 major stock monitoring techniques consist of just-in-time administration (JIT), products requirement preparation (MRP), economic order amount (EOQ), and also days sales of supply (DSI).

A scarcity of supply when and also where it's required can be incredibly harmful. At the exact same time, supply can be believed of as an obligation (if not in an accountancy feeling).

Small organizations will certainly typically keep track of supply by hand as well as identify the reorder factors as well as amounts using spreadsheet (Excel) formulas.

The Best Guide To Inventory Management

Proper supply management approaches vary depending on the industry. An oil depot is able to store large amounts of supply for prolonged periods of time, permitting it to wait on need to get. While storing oil is pricey and also riskya fire in the U.K. in 2005 resulted in numerous extra pounds in damage and finesthere is no risk that look at this now the supply will certainly ruin or go out of design.For business with complicated supply chains as well as producing processes, balancing the dangers of stock gluts and also lacks is specifically tough. To attain these equilibriums, companies have actually created several methods for supply monitoring, consisting of just-in-time (JIT) as well as materials need planning (MRP). Some firms, such as economic solutions firms, do not have physical supply therefore must depend on service procedure administration.

Supply has to be physically counted or determined before it can be placed on a balance sheet. Completed products are completed products readily available for sale to a firm's clients. Depending on the kind of service or item being evaluated, a firm will certainly utilize various supply monitoring methods.

Report this wiki page